From custom prosthetics to entire homes, 3D printing is changing how we design and build almost everything. But what exactly is it?

At its core, 3D printing is a way to turn digital designs into real-world objects by adding material layer by layer. It offers huge possibilities in fields like medicine, architecture, and engineering because it allows for a level of customization, speed, and creativity that traditional manufacturing methods simply can’t match.

This guide is here to help you understand what 3D printing is, how it works, and why it’s such an exciting field for students and future professionals.

TABLE OF CONTENTS

- What is 3D Printing?

- How Does It Work?

- How Is It Used?

- What Career Paths Are Available in 3D Printing?

WHAT IS 3D PRINTING?

3D printing is a way to make real objects from a computer design by building them up layer by layer, kind of like stacking very thin pancakes on top of each other.

It’s also called additive manufacturing because you add material to create something, rather than starting with a big block and cutting pieces away. This is the opposite of how things are usually made in factories, where workers use machines to cut, drill, or carve material away from a larger piece until they get the shape they want.

So while traditional manufacturing takes away material (subtractive), 3D printing adds material exactly where it’s needed (additive).

That means there’s much less waste, and you can make complicated shapes that would be really hard to create by cutting them out of a solid block. You can even print objects with moving parts already inside them or create hollow spaces that you couldn’t reach with normal tools.

HOW DOES 3D PRINTING WORK?

3D printing works through a three-step process that turns a digital idea into a physical object. The process is straightforward but requires precision at each stage to create successful prints.

Designing With CAD Software

The first step is to create a 3D model of the object you want to print. This is done using computer-aided design (CAD) software. Designers can create a model from scratch, modify an existing one, or scan a real-world object to generate a digital file.

You can design anything from simple shapes like boxes and spheres to complex objects like phone cases, toys, or even replacement parts for broken items. The software lets you adjust the size, add details, and make sure everything looks exactly how you want it before printing.

Slicing the Model

The 3D model file itself doesn’t contain the instructions for how to print the object. Before printing, the digital model must be processed by a special program called a “slicer”. This software takes the 3D design and cuts it into thousands of extremely thin horizontal layers.

The software also calculates the best path for the printer to follow, determines printing speed, and adds support structures if needed for overhanging parts. This creates a file with detailed instructions that tell the printer exactly where to place material for each layer.

Layer-by-Layer Printing

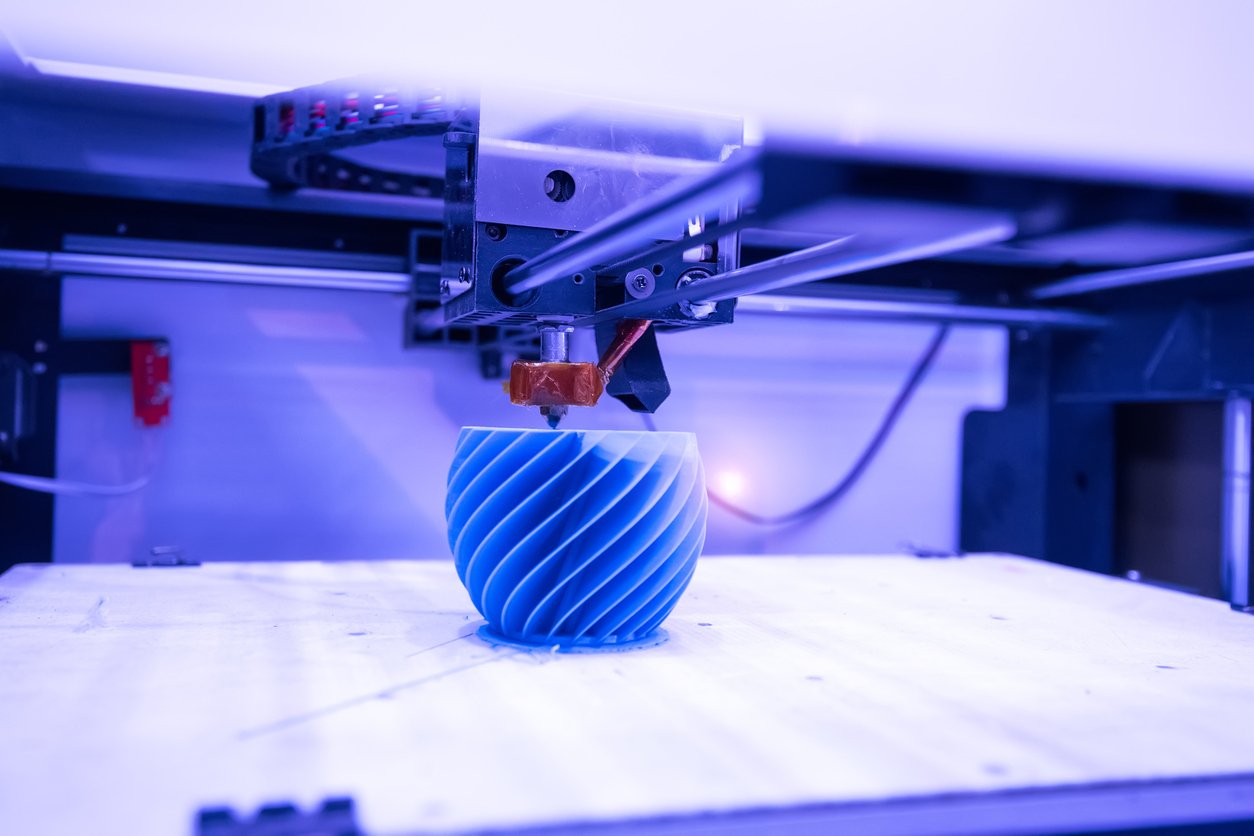

Finally, the printing begins. The 3D printer follows the sliced instructions and starts building from the bottom up. The printer deposits the chosen material (such as plastic filament, resin, or metal powder) one layer at a time onto a build platform. Each new layer is fused to the one beneath it.

This continues until the entire object is built, which can take anywhere from minutes to many hours, depending on the size and complexity.

3D printing builds each layer from the bottom up

3D printing builds each layer from the bottom up

HOW IS 3D PRINTING USED?

3D printing makes it possible to create customized products and prototypes quickly and affordably. The technology is being used in surprising ways across different fields.

Healthcare

Doctors can now create custom prosthetic limbs that fit perfectly for each patient. Similarly, dentists use 3D printers to make crowns, bridges, and even dental implants that match a patient’s mouth exactly.

Some hospitals are even printing models of organs before surgery so doctors can practise complex operations, and researchers are working on printing living tissue and organs for transplant.

A breathable cast created by 3D printing

A breathable cast created by 3D printing

Engineering

Engineers use 3D printing for rapid prototyping. Instead of waiting weeks or months to make a prototype the old way, engineers can print a working model in just a few hours. This lets them test their designs, find problems, and make improvements much faster. Car companies, airplane manufacturers, and electronics companies all use this to develop better products more quickly.

Fashion and Art

Jewelry designers can make intricate pieces with complex patterns and moving parts all printed as one piece. Fashion designers have created entire dresses and shoes using flexible printing materials. Artists are making sculptures with internal structures that could never be carved or molded traditionally.

Architecture and Construction

Architects use 3D printers to create detailed scale models of buildings so clients can see exactly what their project will look like. Entire houses are even being 3D printed using concrete and other building materials. These homes can be built much faster and at lower cost.

3D printing a house out of concrete

3D printing a house out of concrete

WHAT CAREER PATHS ARE AVAILABLE IN 3D PRINTING?

Having a solid understanding of 3D printing technology can be an asset in many fields. Here’s a breakdown of some related jobs:

3D Printing Technician: This is a common entry-level role. Technicians operate and maintain 3D printers, prepare print files, and troubleshoot issues. They work in labs, manufacturing facilities, or design studios.

CAD Designer/3D Modeller: These professionals use software like SolidWorks or AutoCAD to create digital models that are then printed. This role is essential in industries like product design, architecture, and engineering.

Additive Manufacturing Engineer: These engineers focus on optimizing the 3D printing process for production. They select materials, refine print parameters, and ensure quality control—often in aerospace, automotive, or medical device manufacturing.

Industrial Designer: These creatives use 3D printing to rapidly prototype and iterate on product ideas. They often work in consumer goods, electronics, or fashion, where customization and speed-to-market are key.

Architectural Model Maker: Architects and urban planners use 3D printing to create scale models of buildings and landscapes. This role blends technical precision with visual storytelling.

WANT TO LEARN MORE ABOUT 3D PRINTING?

Herzing College’s 3D Printing program takes students through the entire additive manufacturing process. Training covers CAD software, materials science, product design, production processes, quality control, and more.

The program takes just 11 months to complete and includes a four-week internship for hands-on work experience.

Click below to get full program details and chat live with a friendly admissions advisor. We’re here to help!